I finally got my tools in order and took the time to do some work on this smoking hot babe today.

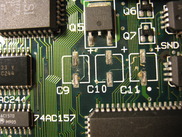

First off, I removed all the nasty caps with my new diagonal cutters. Some of them very easily came off from the PCB all on their own. Others I tugged at a little bit. Some left leads behind that I later had to desolder; the best way to desolder these seems to be to clean them, flux them, head up the lead only (not the corroded solder), and push on it a bit. Sometimes, you can find a bit of shiny late 1980s solder under these leads. The leads that came out with no problem had corrosion even within the footprint of the removed lead.

To clean the board after removing the capacitors, I used 91% isopropyl alcohol (although I'd prefer 99%), a non-abrasive lint-free wipe, and a small brush. I'm still waiting for a horsehair brush, so I used one of those disposable (pre-pasted) toothbrushes instead of what I'd have preferred to use. I splashed a bit of alcohol onto my wipe and proceeded to rub the PCB through the wipe. Most of the crumbly brown and white stuff came off the board with the alcohol and brushing.

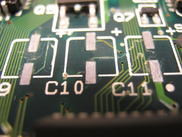

Even after the alcohol, she wasn't looking so good yet. It was time for the flux. I applied flux with a Kester #951 ("no clean", but I clean it anyway) flux pen. Then I heated up the pad with a 750 degrees Fahrenheit iron tip, to try and melt what solder was there. I could often push the surface corrosion away from the solder after I got into it. While the pad was hot, I applied fresh new solder and left a nice wet hump of solder on the pad. I got out my solder wick and wicked the hump away, while at the same time taking advantage of the oft maligned property of solder wick: that it is abrasive. With a few (2 or 3) swipes of the solder wick, the pad became much cleaner. To get things really pretty, I applied flux again, put down more solder, wicked it away, and then cleaned with alcohol (in the same manner as before). With the exception of a few light scratches, the pads looked pretty much new. They'll be much easier to work with and much more receptive of new parts now.

She is looking quite a bit better after this work, as you have seen. Her pads are shiny and fresh. The next step is putting on some nice new orange tantalum capacitors.